Pneumatic systems have been used in automobiles for various applications, ranging from braking and suspension to engine control and transmission shifting. Here are a few examples of pneumatic systems used in automobiles:

1. Breaking Systems

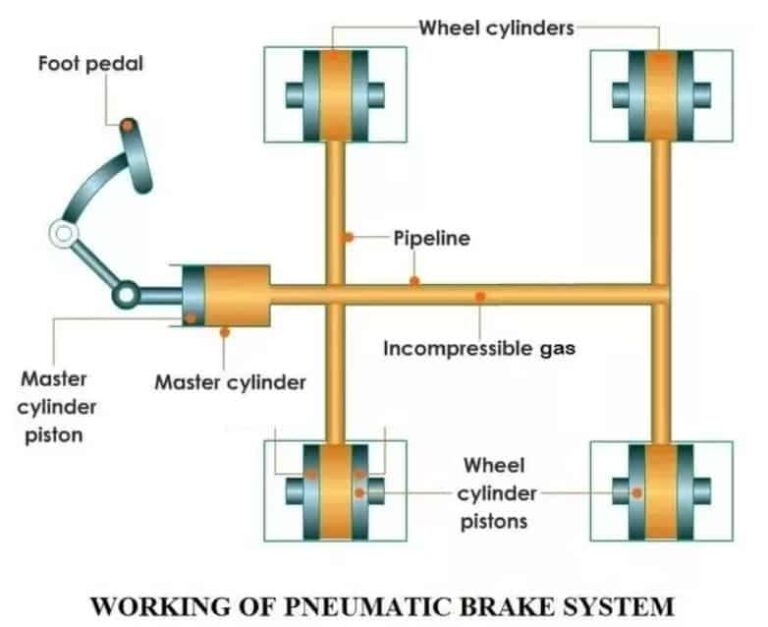

Automotive pneumatic systems have been widely used in braking systems in heavy-duty vehicles, such as trucks and buses. A pneumatic braking system is known as an air brake system, which uses compressed air to activate the brake pads or shoes. The air brake system has several advantages over hydraulic systems, including increased safety, reliability, and efficiency.

One of the significant advantages of an air brake system is its safety. Unlike hydraulic brakes, the air brake system can function even if there is a leak in the system. In a hydraulic system, a leak in the brake line can result in a loss of braking power, making the vehicle difficult to control. In contrast, the air brake system’s dual-circuit design ensures that there is always some level of braking power available, even if one circuit fails.

Another advantage of an air brake system is its reliability. Pneumatic systems are less prone to wear and tear than hydraulic systems, and they are not affected by high temperatures or corrosive fluids. In addition, air brakes require less maintenance than hydraulic brakes, as they do not have any fluid to replace or bleed regularly. This makes air brake systems more cost-effective in the long run.

In conclusion, automotive pneumatic systems, particularly air brake systems, provide a reliable and efficient solution for braking in heavy-duty vehicles. With their safety and reliability benefits, air brake systems have become the standard in commercial vehicles, contributing to improved road safety and reduced maintenance costs.

2. Suspension Systems

Automotive pneumatic systems are also used in suspension systems to improve ride comfort and handling. Pneumatic suspension systems, also known as air suspension systems, use compressed air to adjust the height of the vehicle and absorb shock while driving. The system includes air springs, which replace traditional coil springs and offer better shock absorption and load-carrying capabilities.

Pneumatic suspension systems can adjust the vehicle’s ride height, allowing it to adapt to different road conditions. The system can raise or lower the vehicle’s body, depending on the driver’s preference or the terrain. This feature is particularly useful in off-road vehicles, where ground clearance is essential, or in luxury cars, where ride comfort is a top priority. The ability to adjust the ride height can also improve the vehicle’s aerodynamics, reducing drag and improving fuel efficiency.

Another advantage of pneumatic suspension systems is their ability to provide a smooth and stable ride. The system can adjust the damping characteristics of the shock absorbers to suit the road conditions, ensuring that the vehicle stays stable and comfortable even on bumpy roads. In addition, pneumatic suspension systems can improve the vehicle’s handling by reducing body roll and providing better traction. This makes them an excellent choice for high-performance vehicles that require precise handling and control.

In conclusion, automotive pneumatic systems, particularly pneumatic suspension systems, offer several benefits that can improve the vehicle’s ride comfort, handling, and safety. With their ability to adjust the ride height, absorb shocks, and provide stable handling, pneumatic suspension systems have become a popular choice for luxury cars, off-road vehicles, and high-performance vehicles alike.

3. Engine Control Systems

Automotive pneumatic systems are also used in engine control systems to regulate the air-fuel mixture and control the intake and exhaust valves. In diesel engines, compressed air is used to start the engine by turning the crankshaft. This type of engine starting system is known as an air starter system. The air starter system provides a reliable and efficient method for starting diesel engines, particularly in heavy-duty vehicles that require a lot of torque to turn over.

Pneumatic engine control systems can also regulate the air-fuel mixture in the engine, providing precise control over the combustion process. The system uses sensors to measure the engine’s parameters, such as the air and fuel flow rates, and adjusts the mixture accordingly. This ensures that the engine operates at optimal efficiency, reducing emissions and improving fuel economy.

In addition, pneumatic engine control systems can control the operation of the engine’s intake and exhaust valves. The system uses pneumatic actuators to open and close the valves, allowing the engine to breathe more efficiently. This improves the engine’s performance and reduces emissions by ensuring that the combustion process is more complete.

In conclusion, automotive pneumatic systems, particularly pneumatic engine control systems, provide a reliable and efficient method for regulating the engine’s operation. With their ability to start diesel engines, regulate the air-fuel mixture, and control the intake and exhaust valves, pneumatic engine control systems have become an integral part of modern automotive technology. These systems contribute to improved engine performance, reduced emissions, and better fuel economy, making them an essential component of modern automobiles.

4. Pneumatic Transmission Shifting

Automotive pneumatic systems are also used in suspension systems to improve ride comfort and handling. Pneumatic suspension systems, also known as air suspension systems, use compressed air to adjust the height of the vehicle and absorb shock while driving. The system includes air springs, which replace traditional coil springs and offer better shock absorption and load-carrying capabilities.

Pneumatic suspension systems can adjust the vehicle’s ride height, allowing it to adapt to different road conditions. The system can raise or lower the vehicle’s body, depending on the driver’s preference or the terrain. This feature is particularly useful in off-road vehicles, where ground clearance is essential, or in luxury cars, where ride comfort is a top priority. The ability to adjust the ride height can also improve the vehicle’s aerodynamics, reducing drag and improving fuel efficiency.

Another advantage of pneumatic suspension systems is their ability to provide a smooth and stable ride. The system can adjust the damping characteristics of the shock absorbers to suit the road conditions, ensuring that the vehicle stays stable and comfortable even on bumpy roads. In addition, pneumatic suspension systems can improve the vehicle’s handling by reducing body roll and providing better traction. This makes them an excellent choice for high-performance vehicles that require precise handling and control.

In conclusion, automotive pneumatic systems, particularly pneumatic suspension systems, offer several benefits that can improve the vehicle’s ride comfort, handling, and safety. With their ability to adjust the ride height, absorb shocks, and provide stable handling, pneumatic suspension systems have become a popular choice for luxury cars, off-road vehicles, and high-performance vehicles alike.

Automotive Pneumatic Systems

In conclusion, automotive pneumatic systems play an essential role in modern automobiles. These systems provide reliable and efficient methods for controlling various aspects of a vehicle’s operation, including braking, suspension, engine control, and transmission shifting. The use of pneumatic systems in these areas has contributed to improved performance, reliability, and safety in modern vehicles.

One of the primary advantages of automotive pneumatic systems is their ability to provide precise and reliable control over various aspects of a vehicle’s operation. This level of control allows for more efficient and effective vehicle operation, contributing to improved performance and safety on the road. Additionally, pneumatic systems are often more reliable and durable than traditional mechanical systems, leading to reduced maintenance and replacement costs over time.

Overall, the use of automotive pneumatic systems has revolutionized modern vehicle technology. These systems have become an integral part of modern automobiles, contributing to improved performance, reliability, and safety. As vehicle technology continues to evolve, it is likely that the use of pneumatic systems will continue to play an essential role in the design and operation of future vehicles.

High School Student Project Ideas

Here are a few project ideas for a high school student interested in automobile pneumatic systems:

-

Design and build a pneumatic suspension system: Students can design and build a suspension system that uses compressed air to support the weight of the vehicle. This project would involve research into the principles of pneumatic systems, as well as the design and fabrication of the system.

-

Investigate the use of pneumatic brakes: Students can research the advantages and disadvantages of using pneumatic brakes in automobiles compared to hydraulic brakes. They can also explore the history of pneumatic brakes, the technology behind them, and the current state of their use in the automotive industry.

-

Build a pneumatic engine: Students can research the concept of using compressed air to power an engine and then design and build a simple pneumatic engine. This project would involve the fabrication of the engine, as well as the design and construction of the air compressor and other components.

-

Explore the principles of pneumatic power steering: Students can research the principles of pneumatic power steering and how it differs from hydraulic power steering. They can also design and build a simple pneumatic power steering system, comparing its performance to a traditional hydraulic system.

-

Investigate the use of pneumatic systems in racing: Students can research how pneumatic systems are used in racing, such as in Formula One cars, and how they contribute to the performance of the vehicle. They can also explore the design and fabrication of these systems and compare them to other types of racing systems.